product

Location: Home > product > Laser cleaning machine > Laser cleaning machine series

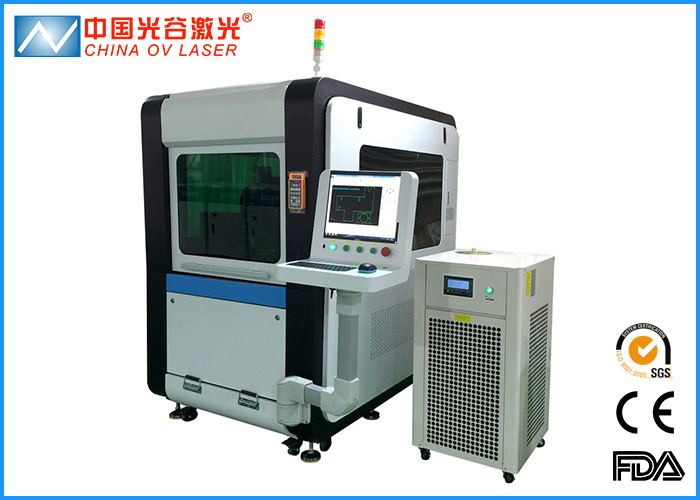

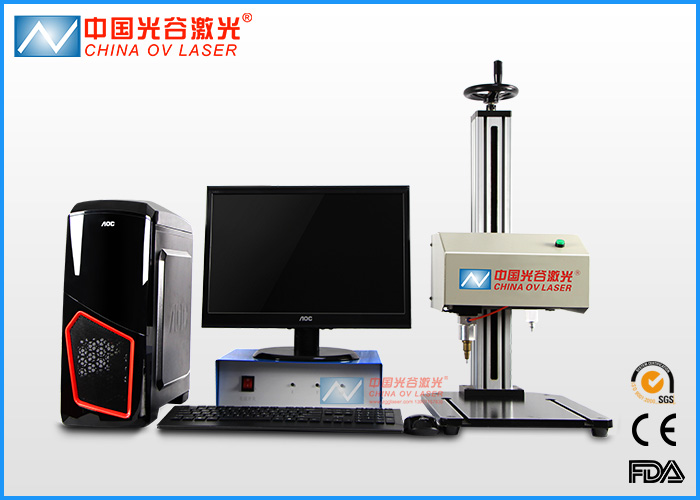

GGJG-Q100 Laser cleaning machine

IntroductionAdvantagesTech dataSamples

ZGG Laser systems offers new and innovative laser ablation technology for industrial surface treatment, cleaning and paint removal.

The laser technology integral to these new laser-cleaning systems helps remove contaminants, production residue and coatings without damaging the substrate. The laser cleaning systems combine power and versatility with the lowest operating cost of all industrial cleaning methods.

We offers innovative laser ablation technology for industrial surface treatment, cleaning, paint removal and cutting applications. Our laser technology removes contaminants, production residue and coatings without damaging the substrate.

Wuhan Optic Valley Laser Equipment Co.,Ltd. Develops a new GGJG-Q series hand-held laser derusting machine,using 100--1000W laser to burn rust and paint on metal surface.

As metals have high reflection,laser pulse is extremely fast and stays on metal surface for very short time to avoid damaging the surface.

On the other hand,the metal rust will be vaporized under laser beams and substrate metals surface will reflect laser beam so that it will not be damaged.Even the letters and bolts will be perfectly cleaned.

The working principle for laser cleaning machine (laser derusting machine) is that contaminant on base materials absorb laser energy and vaporized to realize cleaning.

Laser Cleaning Advantages:

Cleaning with laser has gained so much interest because of the amount of advantages compared to traditional cleaning methods.

The most popular methods of industrial cleaning known today are Chemical, Thermochemical, Thermal, Grinding and Blasting. In many cases, laser cleaning can overcome the downsides of these traditional methods and even improve the production process in general. For every application where laser cleaning is used to replace older techniques, unforeseen advantages came up.

It is impossible to list everything, but these are the most common advantages of laser cleaning:

No medium used, only electricity

Base material is not damaged

Higher levels of 'clean' can be reached

Easy to integrate in a production line

No chemical waste

Local cleaning is possible

Low noise, no dust

Stable process

Low running costs

Lower sensitivity to corrosion after cleaning

Applications:

Complete paint removal

Pre-coating surface preparation / contaminant removal

Pre-treatment to enhance adhesive bonding

Cleaning of large molds

Weld seam pre-treatment

Fast removal of rust/oxides, oil, grease & production residues

Industrial, military, & shipyard - production intensive de-coating

Nuclear de-contamination

Laser cleaning is universally acknowledged as the most reliable and effective solution for all materials with features of non-contact, no grind and no heat effect.

Laser power from 100--500W for different laser cleaning application

High efficient clean speed of 15m²~30m²/h。

Accurate cleaning for exact position and precise size

Widely applied in flat,curved and three-dimensional surface for work piece of elastic material and plastic with very small and deep holes.

Flexible operation for work pieces with complicated geometric construction can be realized by mechanized or hand-held laser cleaning head

No maintenance and no consumables

Dust-free,no chemicals,no pollution

Non-contact cleaning and no damage for substrate

Extremely low cleaning cost and High cleaning efficiency.

Application industry:

Space flight and aviation/ships,automobile/machine manufacturing,mould/hardware tool,food processing/chemical industry,rubber and plastic/tyre,electronics/electrical equipment,weaponry,building materials/cultural relic,steel structural parts,rail transit/machine tool,etc.

Removal for rust ,oil stain,grease,dirt,resin,mold release,oil paint,coating,weld residue,oxide,production residue,etc.

您浏览过的产品

Model | GGJG-Q100 | GGJG-Q300 | GGJG-Q500 |

Laser power | 100W | 300W | 500W |

Machine weight | 50KG | 150KG | 200KG |

Laser gun weight | 1.5KG | 1.5KG | 1.8KG |

Working mode | Manual or auto | ||

Cable length | 3 Mtrs (can be lengthened) | ||

Work distance | 150mm/250mm/500mm | ||

Laser wavelength | 1.064μm | ||

Power supply | 220V / 50Hz / 2A or 380V / 50Hz / 2A | ||

Work temperature | 5℃~45℃ | ||

Work humidity | <90% | ||

Laser class | IV | ||

Address:Wuhan Optical Valley in laser equipment Ltd.

switchboard: 86-27-87207888 Extension;86-27-87207888Turn8188 8288

Marketing Center: 86-27-83566512 83566502 83566517 13707157835

Navigation | Disclaimer | china•ov Wuhan Optical Valley in laser equipment Ltd.All rights reserved 553366